Decoding the Power of Precision: A Beginner’s Guide to CNC Boring and Milling

Welcome to the exciting world of CNC machining! You’re about to dive into a realm where high precision, machine-assisted expertise, and cutting-edge technology converge to create the most intricate and robust components imaginable. Let’s break down the fascinating world of CNC boring and milling machines, tools that have revolutionized manufacturing across industries.

CNC stands for Computer Numerical Control, a system where computer programs control industrial machinery like lathes, mills, and routers. These machines operate with remarkable precision using pre-programmed instructions to create perfect parts. The magic lies in their ability to achieve intricate designs and complex geometries that would be impossible to achieve manually.

CNC boring machines are designed for one specific purpose: creating precise cylindrical holes of various diameters, depths, and locations on a workpiece. They deliver high-precision machining with minimal effort and waste. Imagine drilling a perfectly circular hole in a steel plate or shaping the inner surface of a complex component with pinpoint accuracy.

CNC milling machines take things a step further by offering versatility beyond boring. They’re capable of cutting, shaping, and removing material from a workpiece using a rotating toolhead held by the machine’s structure. They can cut intricate patterns on various surfaces, creating components ranging from simple shapes to complex 3D models.

The beauty of combining CNC boring and milling lies in their synergy. While boring machines focus on making precise holes, milling machines add another dimension to the process – cutting and shaping! This dual-functionality allows for a wide range of applications, from creating custom engine components to generating delicate medical devices.

Before delving further into the specific capabilities of these machines, let’s understand their key components:

Unveiling the Anatomy of a CNC Boring and Milling Machine

1. **Control Unit:** This is the brain of the operation. It receives instructions from computer programs, interprets them, and translates those into precise movements for the machine tools.

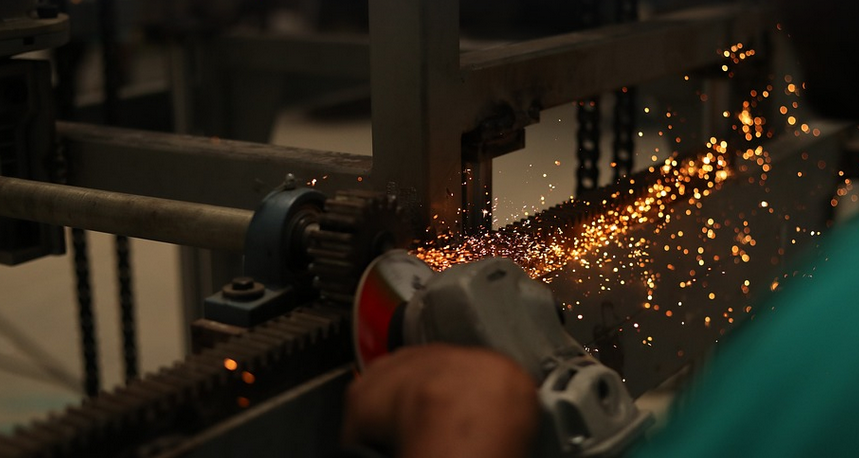

2. **Spindle/CNC Tool Holder:** The heart of the machining process. The spindle rotates at high speeds, powered by electric motors. A tool holder securely supports this rotating tool, which makes contact with the workpiece to create a cut.

3. **Workpiece Holding Mechanism:** This crucial component ensures safe and accurate positioning of the workpiece during machining. A clamping system secures the workpiece in place while allowing for precise movements during machining, preventing movement or slippage.

4. **Feed System:** The feed system is responsible for moving the tool along the desired path on the workpiece. It’s controlled by sophisticated mechanisms that ensure smooth and accurate cuts, minimizing vibrations and surface distortions.

5. **Coolant System:** Workpieces often get extremely hot during machining, especially when using high-speed tools. To prevent overheating, a coolant system is indispensable. Coolant circulates through the work area, cooling the tool and workpiece, thus extending both their lifespan and maintaining precision.

6. **Digital Readout (DR):** For highly accurate machining, especially in complex geometries, this device provides real-time feedback about the position of the tool or the moving part on the machine’s frame

The Power Behind Precision: How CNC Boring and Milling Work

Let’s imagine you need to create a custom engine component for a racing car. You might have an exact CAD model of this component, and now, using the power of a CNC boring and milling machine, you can bring your design to life.

First, the program instructions are loaded onto the control unit, which translates them into specific commands for the spindle, tools, and other components. The machine’s sensors ensure this process is error-free and accurate, ensuring precision in every cut.

The CNC system then guides the spindle to precisely follow the path defined by the CAD model on a workbench. The tool moves through the workpiece, creating a cylindrical hole for a screw or other component. The program also controls the depth of the cut and other parameters like feed speed and cutting direction.

Imagine working on an intricate medical device – a tiny valve for a heart pump. The process requires precision beyond anything possible with traditional machining techniques! CNC boring and milling machines allow us to create these incredibly complex parts with remarkable accuracy, often even at the micro-scale.

Beyond Boring and Milling: Exploring the Diverse Applications

These CNC machining machines are highly versatile, used across a wide range of industries. Here’s a glimpse into their applications:

* **Aerospace**: Creating complex components for aircraft engines, landing gear, and structural parts. Their high precision is key to ensuring safety and performance. * **Automotive**: Manufacturing engine blocks, cylinder heads, transmission components, and intricate automotive parts, all requiring precise tolerances. * **Medical Devices**: Creating implants, prosthetics, surgical instruments, and other medical equipment that demand the utmost accuracy and detail. Medical devices often require precision down to the nanometer level. * **Energy**: Building wind turbine blades, drilling for geothermal energy, and designing custom components for various industrial applications requiring precise control of movement.

Let’s explore some specific examples:

* **Precision Aerospace Components:** These machines are used to manufacture parts required in aircraft and spacecraft, from fuselage sections to intricate landing gear components. * **Medical Devices**: CNC boring and milling machines are essential for creating highly precise parts like implants, artificial joints, prosthetic devices, and surgical tools. * **Automotive Industry:** Car manufacturers use these machines to produce engine blocks, cylinder heads, transmission components, and other parts that need tight tolerances.

Embracing the Future of Machine Manufacturing: CNC Technology’s Impact

The world of CNC boring and milling is constantly evolving. Technologies are improving all the time. This means greater accuracy, faster production times, and even more complex designs.

Some of these advancements include:

* **5-Axis Machining:** This allows for precise machining in any direction, eliminating the need for multiple setups and reducing setup time. * **Cobot Integration**: Collaborative robots are being integrated into CNC systems, allowing for more efficient and collaborative work environments. * **AI-Powered Machining**: Artificial intelligence is used to predict machine failures, optimize cutting parameters, and improve overall machining efficiency.

The future of CNC machines is bright!

CNC boring and milling machines are revolutionizing manufacturing across industries. Their precision, versatility, and ability to handle complex tasks have made them indispensable for a wide range of applications from aerospace to medical devices. As technology continues to advance, these machines will continue to play an even more crucial role in shaping the future of machine manufacturing.

The world of CNC machining is vast and exciting—there’s so much more to explore! Here are some ideas for further learning:

* **Online tutorials and courses:** Take advantage of online resources like YouTube, Udemy, or Skillshare to learn the basics and advanced techniques of CNC machining.

* **Local technical colleges:** Look into local community colleges or vocational schools offering CNC programs, often with access to equipment for hands-on training.

* **Machine tool manufacturers and suppliers:** Many manufacturers have websites that provide detailed information on their products and offer resources for learning about CNC technology.

* **Industry forums and online communities:** Connect with other professionals in the field through online forums, social media groups, or industry conferences to discuss strategies and share knowledge.

Ready to Get Started?

The world of CNC machining is an exciting place. You can start your journey today! Whether you’re interested in the intricate detail of medical devices, the precision of aerospace components, or the potential for automation in everyday manufacturing, CNC boring and milling machines offer a glimpse into the future of manufacturing.

Don’t be afraid to explore this new world and discover its limitless possibilities.