A Flame’s Journey: Understanding the Basics

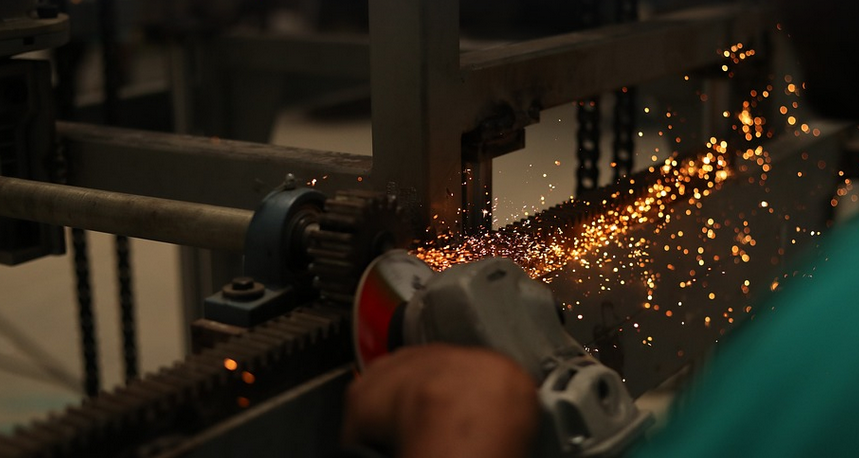

Oxy-acetylene welding, a cornerstone of metalworking for decades, offers unmatched precision and power. This process utilizes an oxyfuel flame – controlled by oxygen and acetylene gas – to melt and fuse metals together. But mastering this ancient art requires understanding its intricacies. The journey begins with dissecting the components and their roles in this fiery dance. First, we have the **torch**, a tool that houses both gases. It’s akin to an artist’s brush; it directs the flame onto the metal being welded. The oxygen-acetylene torch is a marvel of engineering; there are various models with unique features and functionalities. The most common type employs a **blow tube** for creating the initial stream of gas, while others use premixed gases or specialized tips for precise welding. Next comes the **fuel**, the substance that gives life to the flame. Acetylene, a highly flammable gas, is a critical player in this dance. It’s lighter than air and readily ignites when mixed with oxygen. The combination produces a strong, high-temperature flame ideal for cutting and welding. The fuel’s control is crucial; too much, and you risk an uncontrolled burst of flames; too little, and your weld won’t be as effective. Lastly, the **metal being welded**, the canvas upon which the magic happens. It can be steel, aluminum, or even stainless steel in various shapes. Each metal responds differently to heat, requiring specific techniques and preheating strategies for optimal results.

Mastering the Flame: Techniques and Tips

Once you’ve got your basics sorted out, it’s time to delve into the heart of oxy-acetylene welding: techniques. There are several crucial steps involved in this art form, each adding finesse to the final product. The key is practicing these techniques until they become second nature. **1. Preheating:** Before you even touch the metal with your torch, preheating is a must! This helps ensure the metal’s temperature reaches a level where it melts and fuses seamlessly. It’s like warming up an engine before you start it; without it, your welds might not be as strong or smooth. **2. Positioning:** The proper positioning of the torch is crucial for effective welding. Always position it perpendicular to the metal being welded, ensuring a direct flame path. This allows for consistent heat distribution and prevents uneven melting. **3. Movement:** While preheating and positioning are paramount, the art of movement adds finesse. It’s about maneuvering your torch with precision, achieving smooth transitions between welding and cutting motions. Mastering this technique requires practice, patience, and a good understanding of how the flame performs under different pressures. **4. Heat Control:** One of the most crucial aspects – controlling heat output! Use the gas pressure to achieve the desired temperature for your specific metal and weld task. Higher pressure creates a hotter flame, making it best for thicker materials or deeper welds; lower pressure is ideal for thinner metals or more intricate work. **5. Personal Protections:** Safety comes first in any welding process. Your safety gear—protective goggles, gloves, and long-sleeved clothes—acts as your shield against the intense heat and potential hazards. Always practice working with a proper ventilation system to avoid inhaling harmful fumes. ## Finding Your Welding Style: From Beginner to Pro The world of oxy-acetylene welding offers diverse approaches, each tailored for specific needs and preferences. This journey from basic techniques to advanced skills involves embracing various styles and refining your own approach based on experience. **1. The Traditional Approach:** For beginners, the traditional method is a solid starting point. It focuses on understanding fundamental principles and mastering torch handling. Mastering this technique provides a strong foundation for more advanced welding patterns. **2. Welding with Precision:** For those seeking finesse, precision welding techniques are recommended. These involve intricate shaping or joining smaller pieces of metal. Master these techniques to create delicate works of art that blend seamlessly into the metal’s form. **3. Mastering the Art of Cutting:** Beyond welding, cutting is a crucial skill in oxy-acetylene technology. This involves creating precise cuts and shapes on metal using the flame; it requires an understanding of the interplay between fuel flow and heat intensity for optimal results. **4. Seeking Expert Guidance:** Don’t hesitate to seek expert guidance from experienced welders or instructors. Learning from seasoned professionals can accelerate your progress, enhance your skills, and help you avoid potential mistakes. ## The Everlasting Flame: A Conclusion Oxy-acetylene welding remains an enduring part of the metalworking world. Embracing its techniques, mastering its nuances, and understanding its intricacies will unlock a wealth of artistic expression. It’s not just about melting metals; it’s about building something unique and enduring. After mastering these tips, you’ll find yourself in a journey of constant learning and discovery.