Demystifying the Power of a Combined Approach

We live in a world where precision reigns supreme. From intricate medical devices to beautifully crafted furniture, the demand for accuracy is constantly evolving. And at the heart of this pursuit lies a powerful duo: the lathe and milling machine. These machines, often seen as separate entities, actually form a dynamic partnership that unlocks even greater precision when used together.

For those unfamiliar with these workhorses, let’s break down their individual strengths and then explore how they combine to create something truly remarkable.

The Lathe: A Symphony of Precision

Imagine a spinning cylinder, its edges delicately guided by your hand. That’s the essence of a lathe. This machine is a true champion when it comes to shaping and turning materials – literally! It relies on rotational forces to cut away layers of material, resulting in perfectly round objects. Think about creating bowls, cylinders, or even intricate gears with incredible accuracy.

Lathes are masters at working with cylindrical and conical shapes, allowing us to create precise items with exceptional control.

The Milling Machine: The Architect of Precision

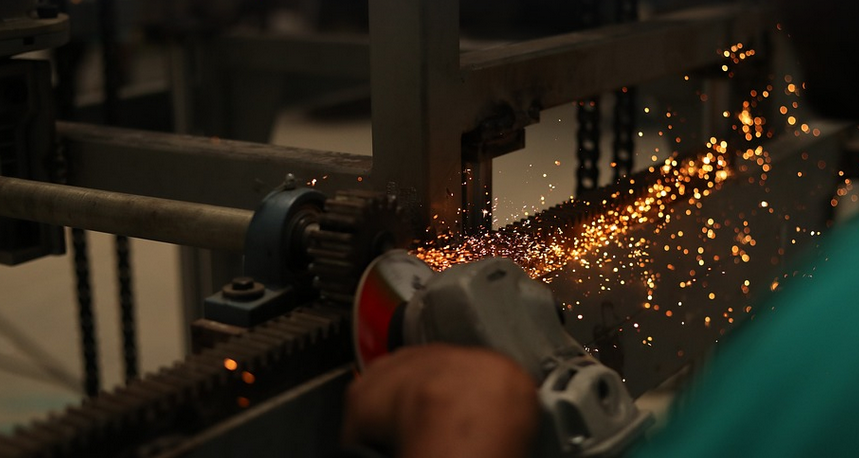

Now, imagine a machine that can cut intricate patterns on various surfaces without compromising on precision. This is the essence of a milling machine. This versatile tool utilizes multiple cutting tools and precisely controlled movements to achieve complex cuts. It’s like an architect painstakingly designing a building block by block.

Milling machines excel in creating slots, pockets, grooves, and other geometries, giving our imagination free reign when shaping objects. From machine parts to custom-designed furniture, milling machines are the key players in bringing intricate dreams to life.

A Powerful Partnership: The Combined Advantage

The true magic of combining a lathe and a milling machine lies in their complementary strengths. Each machine excels in specific tasks, but when working together, they become an unstoppable force. Imagine this: you need to create a complex shaped part for a car engine, with a precisely machined surface that needs to be perfectly smooth.

The lathe can shape the base of the engine block and then, thanks to its ability to cut intricate shapes, create a slot on a specific location. This allows for an easy transition into the milling machine’s domain; it can accurately machine the rest of the part with precision.

Let’s delve deeper into how these two machines work in harmony:

1. **Material Prepping**: Before embarking on a joint operation, you need to prepare your material. The lathe might be used to create rough cuts on a block of wood or metal. This setup will allow the milling machine to carve out more intricate details later on.

2. **Turning and Milling:** The combination offers precise control over material removal. The lathe can be used for turning and shaping, while the milling machine focuses on creating precise cuts that would be difficult or impossible to achieve with just a single machine. This is where the true magic happens: precision combined with speed.

3. **Surface Finishing:** With the lathe’s ability to create smooth surfaces and the milling machine’s precision in surface finishing, you can achieve an almost polished finish on your project. Think about creating something as aesthetically pleasing as a piece of high-end furniture.

4. **Multiple Applications**: This combination of machines opens up a world of possibilities. Imagine crafting custom aerospace components, intricate clock gears for antique restoration, or even building unique sculptures with remarkable detail and accuracy.

Embracing the Future: Adapting to New Challenges

The beauty of these machines lies not just in their historical significance but also in their adaptability. The world constantly evolves, demanding new technologies and processes. As technology advances, we see the rise of CNC (Computer Numerical Control) lathe and milling machine systems.

CNC-controlled lathes and milling machines come equipped with computer programs that dictate the precise trajectory for each tool movement. This translates to even more accuracy, faster production times, and increased automation. As these machines become smarter, so do their applications. You can now use them to create complex geometries, intricate designs, and customized parts that were previously unimaginable.

For those interested in exploring the realm of precision engineering, it’s important to remember that this journey requires not just knowledge of individual machines but also a deep understanding of how they work together. By mastering these powerful tools, you are opening the doors to countless possibilities and crafting a future defined by unparalleled precision.