What is C and C Welding, Exactly?

Imagine this: you have a piece of metal—maybe it’s an engine part, a bridge structure, or even just a small custom sculpture. You want to join two pieces together, but you need something strong, reliable, and capable of handling all sorts of conditions.

That’s where C and C welding comes in! It’s like the ultimate marriage between precision engineering and the art of fusion. C and C (meaning “Chromium-Nickel” ) stands for a family of alloys that deliver superior strength and durability, making them an absolute powerhouse in various industrial settings.

In essence, C and C welding involves joining metal pieces using a specific type of filler material. This filler material is typically composed of chromium, nickel, and molybdenum, all elements known for their resistance to wear and corrosion. Why do we need these alloys? Well, you see, regular steel might be strong enough in some scenarios but struggle when exposed to extreme temperatures or abrasive environments.

C and C welding allows us to create incredibly robust connections that stand the test of time—like a superhero’s power armor, it keeps things safe and sound.

Unveiling the Magic of C and C Welding: The Process

So, what’s the magic behind this welding process? It’s all about wielding heat to melt metal and join it on a molecular level. Okay, maybe not *quite* molecular, but close enough!

We begin by preheating the workpieces—the parts we want to merge. This prepares them for the intense heat that will soften the metals and allow them to flow together without breaking apart.

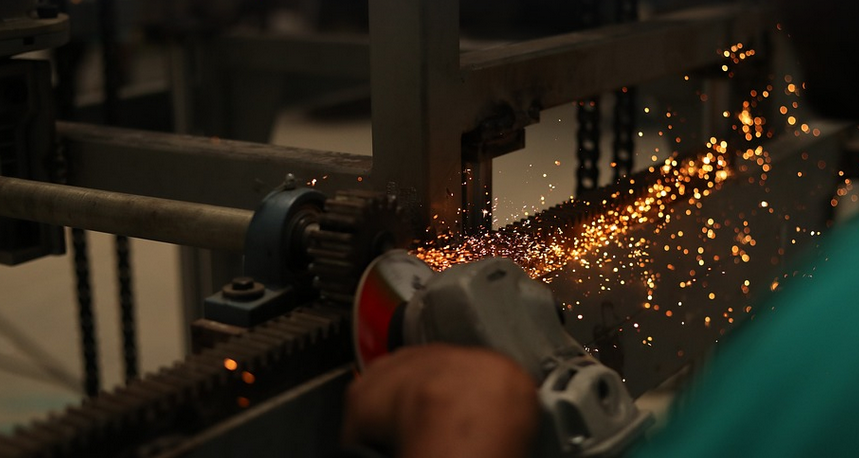

Then comes the welding torch—a handheld device equipped with a specialized nozzle that generates the precisely controlled heat needed for welding. The welder manipulates the torch to melt the metal edges, creating one seamless piece of metal!

The molten metal flows seamlessly into place, bonding the pieces together like puzzle pieces finally finding their perfect fit.

This is where precision plays a key role—it’s about controlling the heat and flow with finesse. The welder has to be skilled in reading the heat readings on the welding machine to ensure a proper weld. It takes practice, patience, and a keen eye!

The Advantages of C and C Welding: A Tailored Approach

C and C welding brings more than just strength—it boasts a suite of benefits that make it stand out in the welding world:

**1. High Strength:** C and C alloys deliver exceptional tensile strength, making them ideal for structural components where heavy loads are expected.

**2. Corrosion Resistance:** The chromium and nickel content in these alloys create a protective layer against rust and corrosion, ensuring long-lasting performance.

**3. Heat Tolerance:** C and C welding alloys have exceptional resistance to heat changes, making them ideal for welding applications that require high temperatures like engine components or machinery operating under extreme conditions.

**4. Versatile Applications:** Their adaptability to diverse materials makes them suitable for various industries. From automotive manufacturing to aerospace engineering, their strength is in demand!

C and C Welding: A Future-Forward Approach

The world of welding is constantly evolving. And C and C welding is embracing advancements that make it even more efficient.

**1. Automation:** Advancements in robotics are making C and C welding processes faster, more precise, and safer than ever before.

**2. Digitalization:** Real-time monitoring and control of welding parameters with digital tools allow for better weld quality control and reduced error rates.

**3. Advanced Materials:** Research into new alloys is constantly pushing the boundaries of what’s possible, leading to even more durable and efficient connections in the future.

C and C welding is not just about joining pieces together—it’s about building a foundation for progress! Their ability to withstand challenging conditions makes them essential for many innovations that are shaping our world.

Exploring the World of C and C Welding

For those wanting to delve deeper into the fascinating world of C and C welding, there’s no shortage of resources available. You can find online forums dedicated to this specific welding technique, where you can connect with other enthusiasts and learn from their experiences.

The beauty of learning about C and C welding lies in its accessibility. Numerous books, videos, and online courses are readily available to provide comprehensive knowledge on the process and different welding techniques.

Don’t shy away from asking questions! The welding community is a network of passionate individuals who are always eager to share their knowledge and experience. It takes time to master this art form, but with dedication and hard work, you can achieve mastery and unlock a whole new world of possibilities in the realm of metalworking!