Understanding the Basics of Amperage in Welding

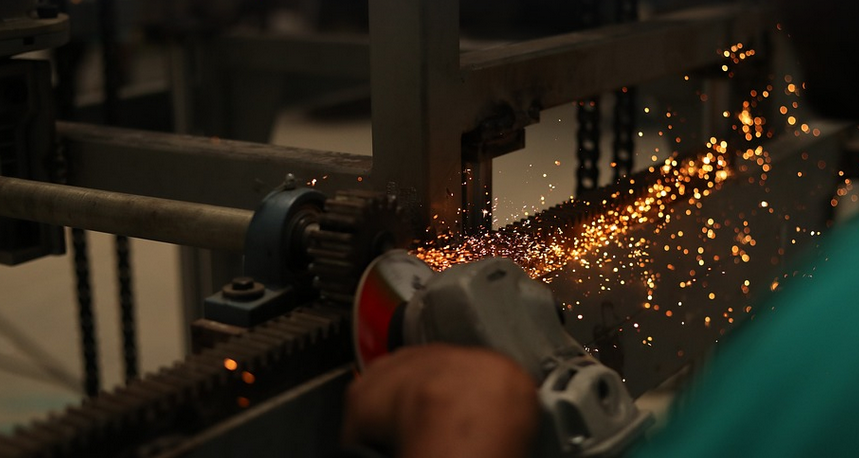

Welding, a powerful process for joining metal parts together, requires precise control and understanding of various factors that influence its effectiveness. Amperage is one such crucial aspect, playing a vital role in determining the intensity and efficiency of welding operations. Let’s delve into the fascinating world of amperage in welding.

Amperage refers to the electrical current flowing through a welding electrode or wire. In essence, it measures how much electric charge is passing through the metal during the welding process. Think of it as the “pulse” of power that drives the arc.

The amperage setting in welding rods directly impacts the welding speed, penetration, and final weld quality. A higher amperage generally leads to faster and more vigorous welding, resulting in a stronger, smoother, and deeper joint. However, too high an amperage can also increase heat input, potentially leading to scorching or even warping of the workpiece.

On the other hand, lower amperage settings allow for more control and precision in welding. This is particularly beneficial when working with delicate materials or intricate designs, allowing welders to achieve a finer degree of control over their welds.

The relationship between amperage and weld penetration can be explained through the concept of “heat input.” When you increase the amperage, more electrical energy is delivered to the welding electrode. This increased energy allows the molten metal to flow deeper into the workpiece, creating a stronger and more penetrating weld.

It’s essential to strike a balance between optimal weld penetration and control. Welding too quickly with high amperage can lead to uneven penetration and potential defects in your welds. Conversely, using low amperage might slow the process down considerably, potentially impacting overall welding efficiency.

Welding rod amperage comes into play in many different applications. For instance, when dealing with steel beams for construction projects, higher amperage settings are often needed to ensure quick and efficient welding of thicker sections. However, for smaller jobs like repairing a bicycle frame or crafting intricate metal art forms, lower amperage settings may be more suitable due their controlled nature.

Choosing the right amperage setting is crucial for achieving the desired weld quality and penetration while avoiding potential issues like warping or incomplete welds. It also plays a significant role in determining the welding speed. A higher amperage translates to faster welding, but it also requires careful monitoring to ensure proper control and avoid overheating.

The type of welding rod used can influence the optimal amperage setting. For instance, stick electrodes, commonly known as “SMAW” or “Stick Welding,” require specific amperage settings depending on the electrode diameter and wire coating. Different welding rods have unique characteristics that play a role in influencing the ideal amperage for optimal results.

Understanding how amperade impacts various aspects of welding can help you make informed decisions about your welding process. Remember, choosing the right amperage setting should be directly linked to the specific situation you’re facing and the desired outcome. The key lies in achieving a balance between speed and precision while maintaining control over the arc.

Experimentation and practice are essential when it comes to mastering the art of welding. As your experience grows, you will develop a better understanding of how different amperage levels affect your welds. Don’t be afraid to test out different settings and observe the results – this is one of the best ways to master the nuances of this fascinating craft.

Welding Rod Amperage: A Detailed Exploration

Welding rod amperage is a critical factor in successful welding. It influences the amount of heat input delivered to the weld pool, which directly affects the weld’s penetration, bead shape, and overall quality.

Understanding the relationship between current, resistance, and applied voltage is essential for optimizing your welding process.

Here’s a deeper dive into amperage:

**1. Amperage Basics:** Amperage represents the flow of electrical current through a circuit, measured in amperes (A). The higher the amperage, the more energetic the electric charge flowing through your welding equipment.

**2. Welding Rod Characteristics:** Different welding rods have varying compositions and diameters that play a role in the required amperage for optimal performance. For instance, thicker-gauge electrodes require higher amperages than thinner ones.

**3. Amperage and Weld Penetration:** The weld penetration is directly influenced by amperage settings. Higher amperage increases the heat input to the welding zone, leading to a deeper penetration in the workpiece. However, too high amperage can also lead to excessive distortion.

**4. Amperage, Speed, and Heat Input:** Amperage is closely linked to welding speed and heat input. Higher amperage results in faster welding, but it’s crucial to monitor the process to avoid overheating or unwanted distortions.

**5. Selecting the Right Amperage:** Finding the optimal amperage setting involves understanding the specific job requirements. Consider factors like weld joint design, material thickness, and desired bead shape when determining the ideal amperage range for your rod type.

Practical Tips for Using Welding Rods with Optimal Amperage

Mastering the art of welding requires a thorough understanding of various aspects like amperage, electrode types, welding techniques, and safety precautions.

Here are some practical tips to ensure optimal performance when using welding rods:

**1. Use Proper Electrode:** Ensure you use the right type of welding rod for your specific application. Different electrodes have different compositions that influence amperage requirements. Select a rod with appropriate specifications based on the material thickness, joint design, and desired weld bead characteristics.

**2. Conduct Pre-Welding Checks:** Before starting any welding job, conduct thorough pre-weld checks to ensure you are using the right amperage setting for your rods and that your equipment is functioning correctly.

**3. Use a Welding Power Supply with Precise Control:** Invest in a welding power supply with precise amperage control features. This will allow you to precisely adjust the current flow based on the specific needs of your job.

**4. Monitor Weld Penetration & Bead Shape:** Pay close attention to the weld penetration and bead shape throughout the welding process. Ensure they are consistent with the desired results.

**5. Maintain Good Welding Technique:** Proper technique is essential for achieving clean, high-quality welds. Utilize proper arc control, maintain a steady rhythm, and keep your welds smooth.

**6. Practice Regularly and Seek Expert Guidance:** Welding rod amperage takes practice to master. Regular practice will help you develop an intuitive sense of proper settings for different welding jobs. If possible, seek guidance from experienced welders or attend welding training courses to hone your skills.

Conclusion

Mastering the art of welding involves understanding and optimizing various parameters like amperage, electrode types, and welding techniques. By using a power supply with precise control features, observing weld penetration and bead shapes, and practicing consistently, you can achieve high-quality welds and build lasting connections in your projects.