What is the D14.3 Specification?

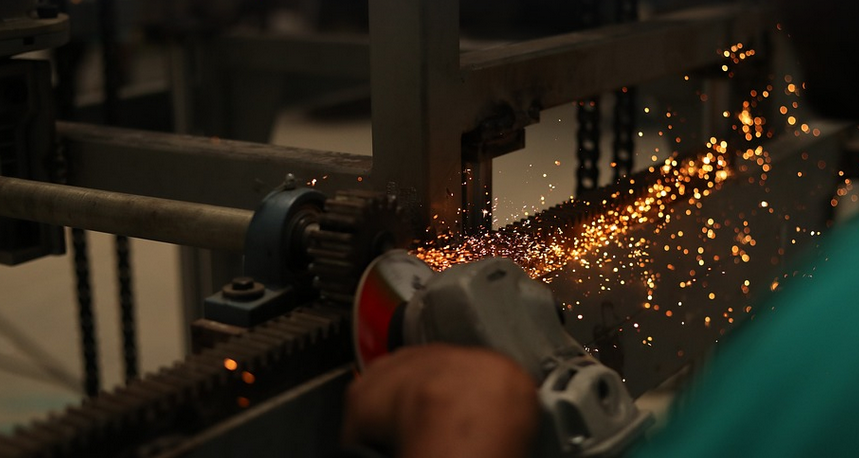

Think of welding as a meticulous art form, requiring precision and expertise to create strong, lasting connections between metals. This is where the D14.3 specification steps in – it’s like a roadmap for welders, offering clear guidelines on how to execute these complex processes safely, reliably, and efficiently.

The D14.3 specification, developed by the American Welding Society (AWS), isn’t just another set of rules; it’s an embodiment of best practices in welding. It addresses everything from welding procedures to material selection, providing a comprehensive framework that ensures consistent quality and safety across all welding operations.

Why D14.3 Matters: A Closer Look at its Significance

So why is the D14.3 specification so crucial for welders and organizations alike? It’s a game-changer in several ways:

* **Safety First:** The primary concern of any welding operation – safety! – is addressed head-on by D14.3. It sets out guidelines on fire safety, arc flash protection, personal protective equipment (PPE) requirements, and environmental awareness to minimize risks during the process.

* **Quality Control:** D14.3 ensures that welds meet stringent quality standards. It covers weld procedures, preheating techniques, joint designs, welding positions, inspection methods, and more. Every detail is laid out for clear execution, reducing errors and ensuring a high-quality product that can withstand demanding conditions.

* **Consistency Across Projects:** Whether you’re working on a bridge construction project or a maintenance job in a power plant, D14.3 acts as a common language. It ensures consistency across projects, even when different teams or locations might be involved, promoting smooth and efficient operations.

The D14.3 Specification: A Breakdown of Its Sections

The D14.3 specification is a comprehensive document; it’s not just one long block of text. It’s organized into sections that delve deep into all aspects of welding, offering detailed guidance at every step.

* **Welding Processes:** The first section dives into the various welding processes covered by D14.3, from stick (SMAW) to MIG, TIG, and even laser welding. It provides a concise overview of each process, highlighting critical parameters like electrode type, amperage, voltage, shield gas selection, and travel speed.

* **Materials & Weldability:** The next section focuses on materials! D14.3 delves into the properties of various metals (steel, aluminum, copper) that might be used in welding projects. It also covers weldability issues, such as preheating requirements, post-weld heat treatment, and potential weld defects.

* **Joint Design & Welding Positions:** D14.3 doesn’t ignore joint design! It provides detailed guidance on the most commonly used joints like butt welds, fillet welds, lap welds, and T-joints, along with welding positions like flat, horizontal, vertical, overhead, and more.

* **Preheating & Post-Weld Heat Treatment:** The sections on preheating and post-weld heat treatment are crucial for enhancing the strength and durability of welded joints. D14.3 offers detailed explanations of different types of preheat treatments and post-weld heat treatment methods to ensure a product that meets specific safety and performance standards.

Staying Ahead of the Curve: The Advantages of Using D14.3

D14.3 isn’t just about compliance – it’s about efficiency, safety, and quality! There are plenty of benefits to incorporating this specification into your welding practice:

* **Reduced Risks:** It minimizes the risk of accidents and injuries by providing clear guidelines on fire prevention, arc flash mitigation, PPE selection, and potential hazards during welding. * **Increased Productivity:** A well-defined process ensures fewer rework errors and more efficient operations. D14.3 promotes consistency in execution, leading to smoother workflows and higher productivity.

* **Streamlined Inspections & Quality Control:** The detailed procedures outlined by D14.3 ensure that every weld meets the required standards and specifications. This leads to improved quality control and streamlined inspection processes.

D14.3: More Than Just a Document, It’s a Foundation for Success

The D14.3 specification isn’t just a document; it’s a foundation upon which success is built. It fosters safety, consistency, and quality by providing clear guidelines for welding procedures. From the welding processes to material selection and joint design, D14.3 lays out the groundwork for safe, efficient, and high-quality welds that stand the test of time.

So, dive into the world of D14.3 and unlock a new level of confidence in your welding expertise!