What is Freezing Point Mineral Oil?

Mineral oil, also known as petroleum jelly or simply oil, is a colorless and odorless liquid derived from crude oil. It’s commonly used in many everyday products like cosmetics and cooking oils due to its non-reactive, lubricating properties. But this seemingly ordinary fluid has some surprising applications, especially when it comes to extreme conditions.

When we talk about freezing point mineral oil, we’re referring to a specific type of mineral oil that exhibits a lower freezing point compared to regular petroleum jelly. This unique characteristic makes it a valuable tool in various applications, particularly where temperatures dip below zero degrees Celsius (32 degrees Fahrenheit). We’ll explore the reasons behind this and delve into its diverse uses.

Why is Freezing Point Mineral Oil So Special?

The lower freezing point of mineral oil is largely attributed to its specific molecular structure. It consists primarily of hydrocarbon chains, which are long carbon-carbon bonds arranged in a relatively compact way.

This arrangement allows the molecules to pack tightly together and form stable structures at low temperatures. As a result, they don’t freeze easily at the typical freezing point of water—which is 0 degrees Celsius (32 degrees Fahrenheit).

So what does this mean for us? Well, it means that freezing point mineral oil can be used in many applications where regular mineral oil would not be suitable.

A World of Applications for Freezing Point Mineral Oil

Imagine a time when the need arose to keep instruments or items from getting damaged by sub-zero temperatures. This is where freezing point mineral oil comes into play. It’s a key ingredient in numerous specialized applications like:

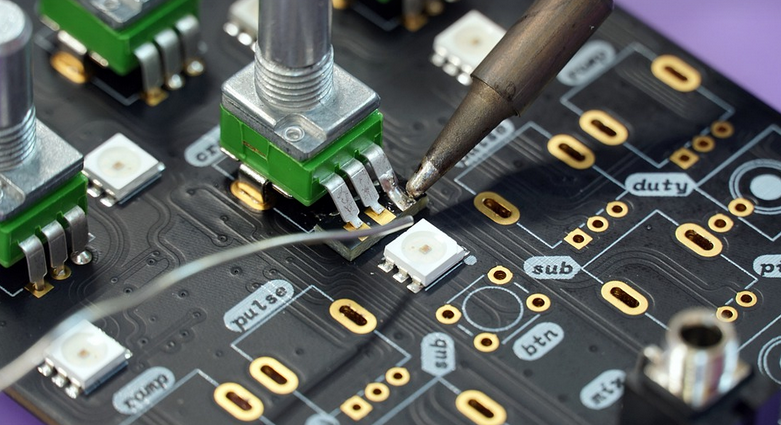

- Electronics and Medical Instruments: Freezing point mineral oil plays a vital role in protecting delicate electronics and medical devices from the damaging effects of extreme cold. The oil acts as a thermal insulator, preventing condensation and corrosion, ensuring proper functionality even in freezing environments.

- Aircraft Manufacturing: In the aerospace industry, the oil is used to lubricate mechanical components exposed to extreme temperatures during flight, such as engine parts or hydraulic systems. This prevents wear and tear caused by rapid temperature fluctuations.

- Industrial Processes: Freezing point mineral oil finds its way into industrial processes where it acts as a lubricant for machinery and equipment operating in harsh environments.

But the applications of freezing point mineral oil don’t stop there. It also plays a crucial role in:

- Food Processing: The oil helps to prevent moisture loss during food processing, preserving its freshness and shelf life.

- Research: It is used as a solvent for certain chemical compounds or for simulating the properties of natural liquids.

- Pharmaceutical Industry: The oil is employed as an ingredient in some medications and formulations due to its compatibility with various substances and its ability to be dispersed easily through different mediums.

Safety Precautions and Environmental Considerations

While freezing point mineral oil offers a range of benefits, it’s crucial to understand and prioritize safety measures when working with this fluid.

The primary concern is the potential for skin irritation or allergic reactions in sensitive individuals. Therefore, wearing gloves and goggles during handling is always advisable. Also, ensure proper ventilation if the oil is used in enclosed spaces to prevent the build-up of fumes.

Moreover, it’s vital to consider the environmental impact of this fluid. It’s essential to dispose of any leftover mineral oil according to local regulations. Additionally, explore eco-friendly alternatives whenever possible to minimize environmental damage.

Freezing point mineral oil is a complex yet fascinating material that unlocks various possibilities in diverse industrial and research applications. Understanding its unique properties and potential benefits will allow us to harness this versatile fluid’s power for innovation and advancement across various fields.