Why Cleanliness Matters

Aluminum welding, while often considered a smooth and efficient process, can become a bit of a puzzle when you throw in the pesky issue of surface contaminants. These little bits and pieces, whether they be dirt, grease, or even rust, act like tiny roadblocks for your weld to happen smoothly. Think of them as unwanted guests who just don’t want to play nice with the molten metal.

Why is this so crucial? Well, imagine welding on a piece of aluminum where you’ve got a layer of grime hiding beneath the surface. Now picture that same grime bridging two pieces of the metal when it heats up. Suddenly, your weld becomes vulnerable to porosity – those little holes in the metal that can weaken the entire structure. It’s like trying to build a house with a leaky roof before you even put down the foundation.

Tools of the Trade: The Basics for Aluminum Cleaning

When it comes to cleaning aluminum before welding, there are a few key tools and techniques at your disposal. Don’t worry about being a pro – we’re just here to get you started on your journey to weld-ready metal.

First things first: the right tools. You’ll want a good selection of brushes – both soft-bristled for delicate areas and stiff ones for stubborn grime. Then, there are power washers, which can be a lifesaver for deep cleaning. Remember, when you use a power washer, always wear protective gear like gloves and safety glasses.

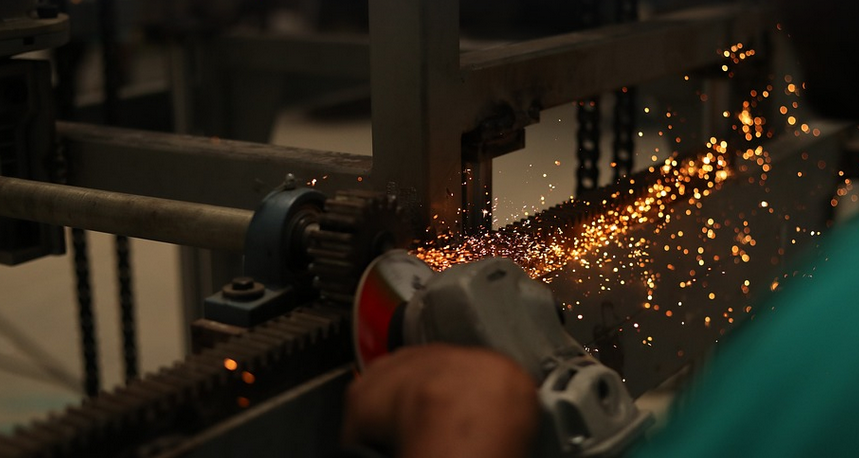

Next, we need to tackle the “rust” factor. A wire brush is your best friend here. It’s specifically designed for removing rust from aluminum surfaces, making it perfect for tackling those stubborn oxidation marks. Just remember to use a gentle touch, as too much force can damage the aluminum.

Finally, our cleaning arsenal needs some special ingredients. Aluminum-specific cleaners, often with a mild acid or a degreaser base, are designed perfectly to remove grease and oil without harming the metal’s integrity. The real magic happens when you use these cleaners in combination with your brushes – imagine it as a team of cleaning superheroes, working together to achieve immaculate results.

The Art of Cleaning: Tips for Success

Now that we have our tools and techniques down, let’s talk about the secret sauce, or rather, the step-by-step process. Remember, practice makes perfect! The more you clean your aluminum before welding, the better you’ll become at it.

First, a thorough rinse is key to removing any remaining cleaning solution. Use clean water and let it run over the surface of your aluminum until most of the residue washes away. This step helps prevent further build-up and keeps things nice and clean.

Next, use your wire brush to gently scrub any loose rust or grease. Be sure to focus on areas where you think contaminants might be hiding, like corners and edges. Remember, too much pressure can damage the aluminum, so use a light touch and feel for resistance – let the brush do its magic.

Finally, clean with your chosen cleaner. Apply it generously to your aluminum, then use your brush or cloth to work in circular motions. This will ensure that every inch of the surface is covered and cleaned. For stubborn grease spots, you might need a few minutes of scrubbing and rinsing before drying. Don’t rush this part; the goal here is thoroughness.

Safety First: A Welder’s Checklist

Welding can be an exciting endeavor, but it’s crucial to remember that safety must always come first. Aluminum welding is no exception.

Here are some essential safety tips for you as you prep your aluminum:

- Wear appropriate personal protective equipment (PPE). This includes welding gloves, a respirator mask, and eye protection to prevent burns, fumes exposure, sparks, and any potential eye injury.

- Have a fire extinguisher handy. Welding can generate heat and spark, creating a potential fire risk. A nearby fire extinguisher will let you address any accidental ignition quickly.

- Work in a well-ventilated area. *Welding produces fumes* that aren’t good for your health, so ensure proper ventilation to maintain air quality and avoid discomfort. **

Remember, being prepared is key when it comes to welding. Keep your tools organized, your workspace clean, and always prioritize safety by following these guidelines.

Beyond the Basics: Advanced Cleaning Techniques

As you advance in the realm of aluminum welding, there are more sophisticated cleaning techniques that can help you achieve exceptional results.

For example, using a sandblaster for extremely stubborn grime or rust might be necessary. However, always remember to use caution when working with abrasive blasting tools as they need proper safety measures and should never be directed at your skin or eyes.

Another option is the “pickling” process. This involves submerging the aluminum in a specially formulated solution before cleaning for optimal rust removal. While it might sound intimidating, pickling is often considered to be a more effective way to clean aluminum than basic methods like power washing or scrubbing.

Remember, when it comes to aluminum cleaning and welding, there’s no single “right” way. Experiment with different techniques and find what best suits your needs and project requirements!