Unlocking Unprecedented Accuracy and Speed

The world of welding is constantly evolving, driven by the demand for even greater precision and efficiency. This evolution has brought us to the forefront of a revolution – handheld metal laser welding machines. These innovative devices are poised to transform how we approach metal fabrication, offering remarkable accuracy, speed, and versatility unlike anything we’ve seen before.

Traditional methods rely on more cumbersome setups and lengthy processes, often resulting in inconsistencies and tedious welds. Enter the handheld laser welder – a game-changer that empowers you with unparalleled control over your welding operation. Imagine being able to seamlessly weld intricate components with unmatched precision, right at your workbench! These machines are truly revolutionizing the way we create.

The secret to this transformative power lies in the nature of the laser itself. Unlike traditional arc-based welding methods that produce heat through an electric current and a molten pool, laser welding utilizes focused, concentrated light beams to generate extremely high temperatures at localized points on the material surface.

How Handheld Laser Welding Machines Work

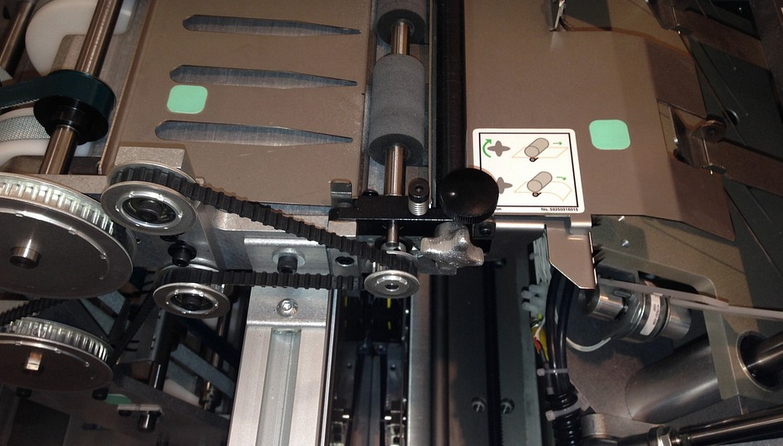

These machines utilize a powerful fiber optic cable system to transmit the laser beam from the machine head to the desired workpiece. The laser penetrates deeply into the metal, generating heat that melts the base metals without damaging surrounding materials. This precise and localized heating process is what contributes to the machine’s remarkable accuracy and speed.

The process of handheld laser welding begins with the operator carefully aligning the laser beam with the intended weld path on the workpiece. The laser then rapidly heats up the metal at a specific point, leading to melting and fusion. With the slightest adjustments, the operator can control the intensity and direction of the laser beam to achieve precise welds.

Handheld laser welding machines boast an array of features designed to enhance their performance, including: precision control systems for accurate beam focusing; automatic beam scanning techniques that allow for fast, automated welding in complex geometries; and even software-controlled weld parameters for optimizing weld quality.

The Advantages of Handheld Laser Welding Machines

The introduction of handheld laser welding machines has significantly shifted the landscape of metal fabrication. This technology opens doors to a world of benefits that traditional welding methods simply cannot match.

Imagine having more flexibility in your work process, with precise welds achievable even within tight spaces or confined areas. These machines offer unparalleled accuracy and control, promising consistent and reliable welds.

Here’s a deeper look at the advantages offered by handheld laser welding machines:

- **Precision & Accuracy:** The lasers in these machines deliver incredible precision in weld seam alignment, resulting in incredibly strong and clean welds.

- **Speed & Efficiency:** Compared to traditional methods, laser welding is remarkably faster. This translates to quicker production times, enabling you to complete projects faster.

- **Versatility:** Handheld laser welding machines can be utilized on various metals like steel, aluminum, and nickel, making them incredibly versatile for diverse applications.

- **Reduced Distortion:** The precise heat control provided by lasers minimizes distortion in the resulting weld. The reduced distortion ensures precise, high-quality welds that meet the highest standards.

- **Safety & Environmentally Friendly:** Laser welding offers significant safety advantages as it eliminates harmful fumes and sparks, promoting a more secure working environment.

Applications of Handheld Laser Welding Machines

The adaptability of handheld laser welding machines has led to their adoption in various industries, making them an integral part of modern manufacturing processes.

Here are some specific applications where these machines have made a significant impact:

- **Automotive Industry:** Laser welding is widely used in the automotive industry for joining auto parts like chassis and body panels.

- **Aerospace Industry:** Precision welding is essential in aerospace applications, where lightweight and high-strength structures are critical.

- **Medical Device Manufacturing:** The precision and consistency of laser welding make it an ideal choice for manufacturing biocompatible medical devices like implants and stents.

- **Electronics Industry:** Electronics manufacturers rely on laser welding to create precise joints in delicate components, ensuring optimal performance and reliability.

The Future of Handheld Laser Welding Machines

The handheld laser welding machine is not just a tool; it’s a catalyst for innovation in the world of metal fabrication. This technology is constantly evolving and pushing the boundaries of what is achievable in this field.

We can expect to see even more advancements in the coming years, including:

* **Miniaturization:** Expect smaller, lighter, and more portable laser welding machines that offer greater versatility.

* **Advanced Automation:** The integration of artificial intelligence (AI) and machine learning into laser welding systems will further enhance accuracy and automation.

* **New Material Applications:** Laser welding capabilities are expanding to new materials, including advanced alloys and composites, opening up exciting possibilities for various industries.