What is Galvanised Steel?

Galvanised steel, also known as verzinkte or zinc-coated steel, is an incredibly versatile material used in everything from construction and manufacturing to automotive and agricultural applications. The process involves applying a layer of zinc to the surface of carbon steel, creating a protective coating that significantly increases its lifespan. This protective coat acts as a shield against rust and corrosion, even in harsh weather conditions.

This galvanization process not only enhances the longevity of the steel but also improves its durability. Think about it: when you’re handling heavy equipment or building structures exposed to the elements, the added protection from galvanisation makes those materials more resilient. The zinc acts as a sacrificial anode; meaning it corrodes first in the presence of moisture and oxygen, protecting the underlying carbon steel.

Why MIG Welding is Preferred for Galvanised Steel

MIG welding is an excellent choice for joining galvanized steel due to its speed, proficiency, and versatility. Here’s why: * **Speed:** MIG welding offers rapid heat input, allowing you to weld thicker pieces of galvanised steel quickly and efficiently. The high-speed welding process combined with the use of solid wires reduces the overall welding time compared to other methods like TIG welding. This allows for faster fabrication and assembly processes. * **Ease of Use:** MIG welding is known for its simplicity and ease of operation. It requires less technical expertise compared to TIG welding, making it accessible for beginners as well as experienced professionals. The basic setup of the equipment—the welder, wire feed system, gas supply, and shielding gas nozzle—is straightforward, enabling efficient and consistent weld performance. * **Ease of Maintenance:** As a user-friendly process, MIG welding does not require frequent maintenance. The welding gun and electrode wires are relatively easy to replace, ensuring smooth operation even after extended usage.

Moreover, the inherent robustness of galvanized steel further enhances the reliability of MIG welded joints. The zinc coating on galvanized steel is known for its resilience against corrosion. It offers a barrier that safeguards against moisture penetration and chemical damage, leading to enhanced durability in the weld joints themselves.

Understanding the Welding Process

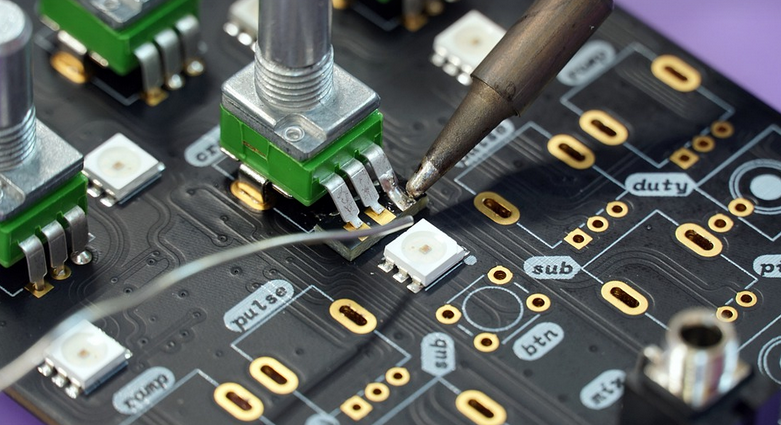

MIG welding involves a few key steps: * **Preheating:** Before welding, typically using a torch or heating element, you need to preheat the metal. This helps make it more malleable and reduces the risk of cracking during the weld. * **Welding Action:** The MIG gun delivers thin wires, which arc between the welding electrode and the base metal. This creates an electrical current that melts the filler wire and joins the pieces together. * **Shielding Gas:** The shielding gas (often Argon or CO2) protects the molten weld pool from atmospheric contamination, ensuring proper flow and integrity of the weld. * **Cleaning:** After welding, it’s essential to clean the weld area for optimal results and smooth finish. This can be done using a wire brush, grinder, or sandpaper to get rid of any slag build-up that might inhibit further welding or reduce weld quality.

MIG welding is an all-around process, suitable for different shapes, thicknesses, and types of galvanized steel. The versatility makes it ideal for applications where speed and cost-effectiveness are key factors.

Advantages of MIG Welding for Galvanised Steel

* **Speed:** The rapid heat input allows for faster welding speeds, saving you significant time compared to other welding techniques. * **Portability:** MIG welding units are relatively portable. This means you can bring them to various locations where the job requires welding—be it a construction site, factory floor, or even your garage. * **Efficiency:** With proper setup and use of MIG welding equipment, you can expect high efficiency. The process is reliable, consistent, and delivers high-quality welds. * **Versatility:** MIG welding works on different thicknesses, shapes, and types of galvanized steel. It’s a robust method suitable for various applications in construction, manufacturing, and more

MIG welding for galvanised steel offers a streamlined approach to join these materials. The process reduces the need for complex setups or multiple steps, which saves time and resources. This technique is considered one of the most efficient methods for welding galvanized steel.

Safety Precautions When Welding Galvanized Steel

Welding steel always carries inherent risks, and it’s crucial to prioritize safety: * **Eye Protection:** Wear appropriate eye protection (goggles or full-face shields) as sparks can fly off during the welding process. These shields are designed to safeguard your eyes from potential burn injuries. * **Ventilation:** Ensure adequate ventilation in your workspace by using exhaust fans or working outdoors when possible. Welding fumes can be harmful if inhaled, so ensure proper ventilation. * **Fire Safety:** Be aware of fire hazards and maintain a safe distance from flammable materials. Keep flammable liquids away from the welding area to prevent accidents. * **Skin Protection:** Wear heat-resistant clothing and gloves to protect your skin from potential burns or irritation. Welding sparks can sometimes cause skin damage, so it’s vital to use protective gear as recommended by manufacturers.

Always follow safety guidelines and wear appropriate welding gear when working with any type of welding equipment.

Conclusion: MIG Welding for Galvanised Steel

MIG welding is a well-established and incredibly efficient method for joining galvanized steel. It offers speed, ease of use, portability, and versatility—all key factors that make it one of the most popular choices for professionals and DIY enthusiasts alike.

With proper training and safety precautions, MIG welding is an excellent technique to enhance your welding skills. By understanding the process, benefits, and safety considerations, you can confidently tackle various projects involving galvanized steel.