A Deep Dive into the World of TFT Recycling

In an increasingly conscious era, where we’re all trying to minimize our environmental impact, recycling has become more than just a trend; it’s a necessity. And when it comes to “t n t” (or technically, ‘tin-plated nickel-titanium’), the subject of recycling is gaining traction among environmentally-conscious individuals and organizations. So what exactly are these materials, and why should we care about recycling them?

T n t recycling refers to the process of collecting, processing, and repurposing tin-plated nickel-titanium (TiNi) alloys for various applications. These alloys, known for their exceptional strength, durability, and biocompatibility, are used extensively across industries like aerospace, medical devices, electronics, and even jewelry making.

The unique properties of TiNi alloys make them incredibly useful yet challenging to recycle due to the complex combination of materials involved. These alloys often contain varying percentages of different metals, including titanium, nickel, and tin, each with distinct recycling needs and complexities.

Understanding the process starts with recognizing the types of “t n t” materials in circulation:

* **Medical Implants:** Titanium-nickel alloys play a critical role in medical implants like orthopedic devices, knee replacements, and dental restorations. These implants are designed for long-term use and biocompatibility, requiring meticulous recycling processes to ensure no harmful metals leach into the environment.

* **Electronics Components:** TiNi alloys find their way into electronic components such as sensors, connectors, and coils. Their unique properties offer excellent resistance to corrosion and wear, making them ideal for high-performance electronics.

* **Jewelry & Crafts:** TiNi’s ability to be worked into intricate designs makes it popular in jewelry crafting. Recycling these alloys ensures the valuable metals are reused, potentially creating a circular economy within the creative space.

As with any material that’s been used for various purposes, there are challenges associated with recycling “t n t.” The complexity of the materials necessitates a well-planned process to ensure safety and efficiency.

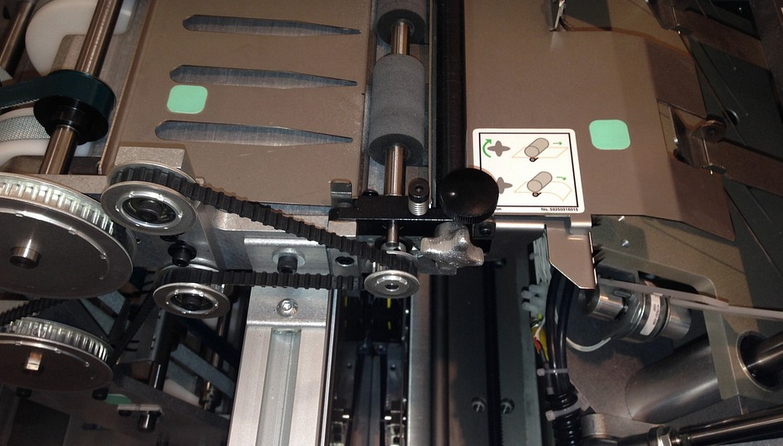

First, the alloys need to be sorted and separated based on their respective composition and melting points. This step requires the use of specialized equipment like magnets, eddy current separators, and X-ray fluorescence analysis for accurate identification.

Then comes the melting process – a key stage in recycling any metallic alloy. It involves heating the alloys to high temperatures (usually above 1000°C) within controlled environments that prevent contamination and ensure a clean melt. This melted mixture then undergoes further processing for specific applications.

Recycling “t n t” can have significant advantages for both environmental protection and economic growth. It minimizes the amount of waste products going to landfills, reducing the strain on natural resources and contributing to a cleaner environment.

The recycling of “t n t” can also create new opportunities for businesses and job creation in the circular economy. The demand for recycled materials is constantly growing as more companies strive to minimize their environmental impact and adopt sustainable practices. Businesses that specialize in recycling “t n t” alloys could offer valuable services to manufacturers, government agencies, and consumers.

In a world increasingly focused on sustainability, the potential of “t n t” recycling is immense. The journey towards a more circular economy starts with understanding and embracing these opportunities for a cleaner, greener future.