Part I: Unveiling the Magic of TIG Weaving

TIG welding, known for its precision and versatility, offers a unique way to enhance steel structures, create intricate art pieces, and even delve into the fascinating world of jewelry crafting. One of its most captivating applications is weaving fabric with TIG welds. But what exactly makes this method so special?

TIG welding weaves utilize the heat-resistance of Tungsten Inert Gas (TIG), a process that allows for precise control over the flow of electricity and molten metal, making it ideal for intricate welding work. The unique combination of TIG’s precision and the artistic nature of weaving results in stunningly beautiful structures, from delicate jewelry to functional steel components.

The beauty of TIG welding weaves lies in their ability to create a variety of patterns and textures. These welds are more than just simple connections; they act as building blocks for intricate designs, allowing you to play with different weaving techniques like:

- Zig-zag Weave: This classic weave pattern creates a diagonal effect that adds dynamism and character.

Diamond Pattern: This intricate design employs overlapping weld lines to create a geometrically patterned surface.

Spiral Weaves: These mesmerizing patterns start with a central point of contact, gradually spiraling outward to create a visually dynamic effect.

Part II: Understanding the Weaving Process

The process of TIG welding weave involves a few key steps:

1. **Preparation:** The first step is to prepare the steel materials for weaving by cutting them into desired shapes and ensuring they are free from any imperfections.

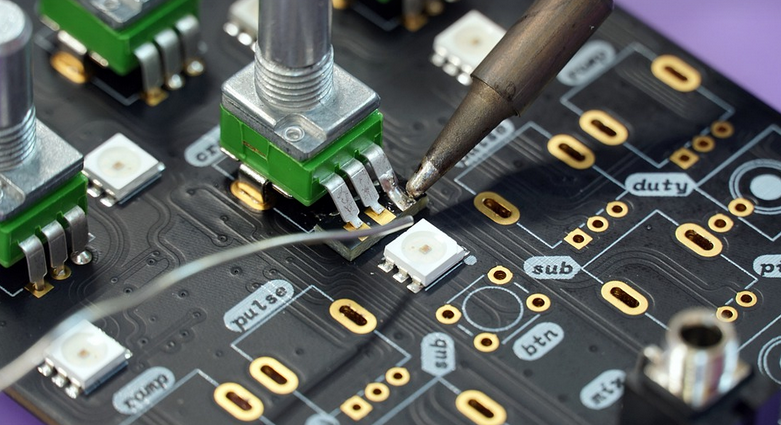

2. **Welding Technique:** A TIG torch is used to precisely control the heat and melt the metal at specific locations, creating a controlled weld seam.

3. **Weaving Pattern Application:** With the welded seams forming the structure of the chosen pattern, it’s time to weave them together to create the desired geometric design.

4. **Finishing Touches:** Once the weaves are complete, you can utilize grinding and polishing techniques to smooth out any rough edges and enhance the overall finish.

This intricate weaving process demands a keen eye for detail and an understanding of metalwork principles. However, with practice and patience, anyone can master this skill.

The beauty of TIG welding weaves lies in their potential to create truly unique pieces. You can incorporate different materials like copper or brass alongside steel, allowing for even more design possibilities.

Part III: Exploring the Applications of TIG Weaving

TIG welding weaves have a range of applications that extend beyond artistic creations:

1. **Engineering and Construction:** In construction and engineering, TIG weaving can create durable and aesthetically pleasing components for bridges, skyscrapers, and other large-scale structures.

2. **Jewelry Making:** The intricate designs and fine detail work in TIG welding weaves are ideal for creating beautiful jewelry pieces that blend functionality and artistry.

3. **Art Installations:** Large-scale artistic installations made with TIG welding weaves can showcase the beauty of this technique, transforming spaces into captivating works of art.

4. **Custom Furniture:** TIG weaving can help create customized furniture designs that incorporate unique patterns and textures, allowing for truly personalized pieces.

5. **Artistic Exploration:** For those looking to explore new frontiers in welding artistry, TIG weaves offer a creative outlet that allows them to experiment with different patterns and materials.

The versatility of TIG welding weaves makes this technique an invaluable tool across various industries, enabling the creation of unique and functional pieces.

Part IV: The Future of TIG Weaving

As technology advances, so too will the application of TIG weaving. Next-generation welding techniques promise to push the boundaries of what’s possible with this art form.

1. **Automation:** The integration of automated welding systems could streamline the process and allow for greater precision and consistency in weave patterns.

2. **Material Innovations:** As researchers develop new alloys and materials, TIG weaving can leverage these advancements to create even more innovative and visually stunning designs

3. **Evolving Techniques:** New welding techniques like laser-aided welding could further enhance the intricate details and unique textures achievable through TIG weaves.

The future of TIG weaving is bright, with potential for wider adoption across various industries as the technique continues to evolve.

Further Exploration

For those looking to dive deeper into the world of TIG welding and weaving, there are numerous resources available:

* **Online tutorials:** YouTube channels and online learning platforms offer videos and step-by-step guides on how to perform TIG welding weaves.

* **Welding guilds and workshops:** Organizations like AWS (American Welding Society) provide workshops and events where individuals can learn from experienced professionals and connect with fellow enthusiasts.

* **Art schools and colleges:** Courses in welding and fabrication art at art schools or specialized technical institutions offer hands-on learning opportunities to master TIG weaving.

By exploring these resources, you can embark on a journey of discovery into the fascinating world of TIG welding weaves.